ABOUT HI-TECH WELDING

Laser, tool and die, TIG and MIG Welding

Hi-Tech Welding, located on the R&D/Leverage campus in Lee’s Summit, Missouri, stands as a beacon of unwavering dedication to quality, service and reliability. Our hallmark is delivering superior workmanship and ensuring swift turnarounds that will align with your stringent standards. Committed to excellence, we eagerly anticipate the opportunity to long-lasting business relationships with our clients.

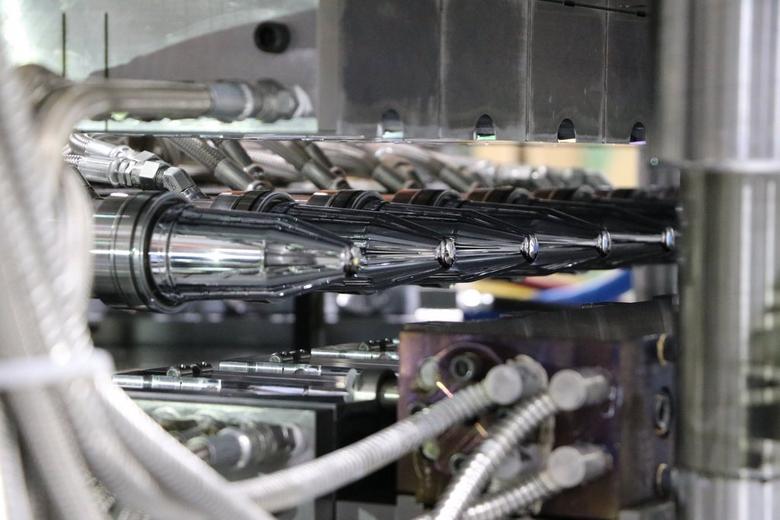

Choosing Hi-Tech welding for your laser welding service presents a distinct advantage: minimal heat sink and negligible buildup, showcasing our technological proficiency, cutting-edge equipment, and extensive experience in meeting any welding requirements.

Our rich expertise spans years of working with an array of exotic metals across varied tooling, specializing notably in laser, tool and die, TIG, and MIG welding techniques.

We know molds.TM

©2024 ADLER INDUSTRIAL SOLUTIONS INC.

Contact Us

We want to learn more about you and how we can help.

Main Office

One Applied Parkway

Omaha, NE 68154

info@adlertooling.com

(415) 329-6877